Title: The Mainstream DC-DC Converters Production Process: A Comprehensive Overview

Introduction (100 words) DC-DC converters play a crucial role in modern electronics, enabling efficient power conversion and management. These devices are widely used in various applications, including renewable energy systems, electric vehicles, telecommunications, and consumer electronics. Understanding the production process of mainstream DC-DC converters is essential to appreciate their functionality and reliability. In this article, we will delve into the intricacies of the production process, exploring the key steps involved in manufacturing these vital components.

1. Design and Specification (200 words) The production process of DC-DC converters begins with the design and specification phase. During this stage, engineers determine the converter's electrical and mechanical requirements, considering factors such as input and output voltage levels, power rating, efficiency, and size constraints. Designers also select the appropriate topology, such as buck, boost, or buck-boost, based on the specific application requirements.

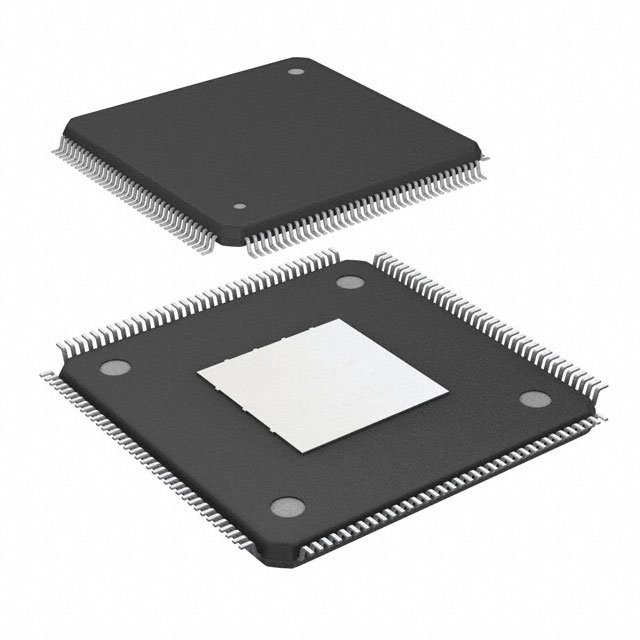

2. Component Selection and Procurement (200 words) Once the design is finalized, the next step involves selecting and procuring the necessary components. This includes choosing the appropriate semiconductor devices, passive components, magnetic components (inductors and transformers), and control circuitry. Manufacturers often collaborate with trusted suppliers to ensure the availability of high-quality components that meet the required specifications.

3. PCB Layout and Assembly (250 words) The printed circuit board (PCB) layout is a critical aspect of DC-DC converter production. The layout design involves placing the components on the PCB and routing the necessary electrical connections. Careful consideration is given to minimize noise, optimize thermal management, and ensure proper grounding. Advanced computer-aided design (CAD) tools are employed to create the layout, which is then sent for fabrication.

Once the PCBs are fabricated, the assembly process begins. Surface mount technology (SMT) is commonly used, where components are mounted directly onto the PCB using automated pick-and-place machines. Through-hole components may also be used for specific applications. The assembly process involves soldering the components onto the PCB, ensuring proper electrical connections.

4. Testing and Quality Control (250 words) After assembly, the DC-DC converters undergo rigorous testing and quality control procedures. Various tests are conducted to verify the converter's performance, efficiency, and reliability. These tests include input/output voltage regulation, load regulation, efficiency measurement, temperature testing, and electromagnetic compatibility (EMC) testing. Manufacturers employ specialized test equipment and automated testing procedures to ensure consistent quality and reliability.

5. Enclosure and Packaging (200 words) Once the converters pass the testing phase, they are enclosed and packaged to protect the sensitive components from environmental factors and mechanical stress. The enclosure may be made of plastic or metal, depending on the application requirements. The packaging process involves sealing the converter, adding necessary connectors, and labeling for identification.

6. Final Inspection and Packaging (150 words) Before the DC-DC converters are ready for shipment, a final inspection is conducted to ensure that they meet the required standards and specifications. This inspection includes visual checks, functional testing, and verification of labeling and documentation. Once approved, the converters are packaged appropriately for shipment, ensuring safe transportation to customers.

Conclusion (100 words) The production process of mainstream DC-DC converters involves several crucial steps, from design and specification to final inspection and packaging. Each step requires careful attention to detail, quality control, and adherence to industry standards. By understanding this production process, we gain insight into the complexity and precision involved in manufacturing these essential components. As technology continues to advance, the production process of DC-DC converters will evolve, incorporating new materials, designs, and manufacturing techniques to meet the ever-growing demands of the electronics industry.