What are the purchasing models for the latest Rotating potential meter device components?

Title: Exploring Purchasing Models for the Latest Rotating Potential Meter Device ComponentsIntroduction (100 words) The rotating potential meter device, also known as a potentiometer, is a widely used electronic component that measures electrical potential difference. As technology advances, the demand for more efficient and accurate potentiometers has increased. This article aims to explore the various purchasing models available for the latest rotating potential meter device components, providing insights into the options and considerations for buyers.1. Traditional Retail Purchasing (200 words) The traditional retail purchasing model involves buying rotating potential meter device components from physical stores or authorized distributors. This model offers the advantage of immediate availability, allowing buyers to inspect the components before making a purchase. However, it may have limitations in terms of product variety and pricing, as physical stores often have limited stock and higher overhead costs.2. Online Retail Purchasing (200 words) Online retail platforms have revolutionized the way we shop, and purchasing rotating potential meter device components online offers several advantages. Online retailers provide a vast range of options, allowing buyers to compare prices, read reviews, and make informed decisions. Additionally, online platforms often offer competitive pricing due to lower overhead costs. However, potential drawbacks include longer delivery times and the inability to physically inspect the components before purchase.3. Direct Manufacturer Purchasing (200 words) Directly purchasing rotating potential meter device components from manufacturers can be an attractive option for buyers. This model eliminates intermediaries, allowing for potentially lower prices and direct communication with the manufacturer. Buyers can also benefit from customization options and technical support directly from the source. However, this model may have higher minimum order quantities and longer lead times, making it more suitable for bulk purchases or specific requirements.4. Distributor Purchasing (200 words) Distributors act as intermediaries between manufacturers and buyers, offering a range of rotating potential meter device components from various manufacturers. This model provides convenience by consolidating multiple brands and products in one place. Distributors often have established relationships with manufacturers, ensuring reliable supply chains and technical support. However, prices may be slightly higher due to the distributor's margin, and customization options may be limited compared to direct manufacturer purchasing.5. Subscription-Based Purchasing (200 words) Subscription-based purchasing models have gained popularity in recent years. This model allows buyers to subscribe to a service that provides rotating potential meter device components on a regular basis. Subscriptions can be tailored to specific needs, ensuring a steady supply of components without the hassle of repeated ordering. This model is particularly beneficial for businesses with consistent component requirements. However, it may not be suitable for buyers with fluctuating or unpredictable demands.Conclusion (100 words) In conclusion, the latest rotating potential meter device components can be purchased through various models, each with its own advantages and considerations. Traditional and online retail models offer convenience and variety, while direct manufacturer purchasing provides customization options and potential cost savings. Distributors offer a balance between convenience and technical support. Subscription-based models cater to businesses with consistent component requirements. Ultimately, buyers should carefully evaluate their needs, budget, and preferences to determine the most suitable purchasing model for the latest rotating potential meter device components.

What are the product features of Rotating potential meter?

Title: Exploring the Versatile Features of Rotating Potential MetersIntroduction (100 words) Rotating potential meters, also known as rotary potentiometers or simply potentiometers, are versatile electronic devices widely used in various industries and applications. These devices offer a range of features that make them indispensable in measuring and controlling electrical signals. In this article, we will delve into the product features of rotating potential meters, exploring their functionality, types, applications, and advantages. By the end, you will have a comprehensive understanding of these devices and their significance in modern technology.1. Functionality of Rotating Potential Meters (200 words) Rotating potential meters are primarily used to measure and control electrical signals. They consist of a resistive element, a wiper, and terminals. The resistive element is typically a carbon or conductive plastic track, while the wiper is a movable contact that slides along the track. As the wiper moves, it changes the resistance between the terminals, allowing for precise control of the electrical signal.2. Types of Rotating Potential Meters (200 words) There are several types of rotating potential meters available, each designed for specific applications. The most common types include:a. Linear Potentiometers: These potentiometers have a linear resistive element, allowing for linear changes in resistance as the wiper moves. They are commonly used in audio equipment, robotics, and industrial control systems.b. Logarithmic Potentiometers: Also known as audio taper potentiometers, these devices have a logarithmic resistive element. They are widely used in audio equipment, such as amplifiers and mixers, to provide smooth volume control.c. Multi-Turn Potentiometers: Unlike standard potentiometers, multi-turn potentiometers offer multiple revolutions of the wiper. This feature allows for precise adjustments in applications where fine control is required, such as in scientific instruments and calibration equipment.3. Applications of Rotating Potential Meters (300 words) Rotating potential meters find applications in various industries and fields due to their versatility. Some notable applications include:a. Audio Equipment: Potentiometers are extensively used in audio equipment to control volume, tone, and balance. They provide a smooth and accurate adjustment of sound levels, enhancing the overall listening experience.b. Industrial Control Systems: In industrial settings, potentiometers are used to control motor speed, position, and other parameters. They play a crucial role in automation systems, allowing for precise control and monitoring of machinery.c. Robotics: Potentiometers are employed in robotics to measure joint angles and positions. They enable accurate control of robotic arms and other moving parts, ensuring precise movements and coordination.d. Test and Measurement Instruments: Potentiometers are essential components in various test and measurement instruments, including oscilloscopes, signal generators, and power supplies. They enable calibration and adjustment of these instruments, ensuring accurate readings and reliable performance.e. Automotive Industry: Potentiometers are used in automotive applications, such as throttle position sensors, steering angle sensors, and HVAC controls. They provide accurate measurements and control in critical systems, enhancing safety and performance.4. Advantages of Rotating Potential Meters (200 words) Rotating potential meters offer several advantages that contribute to their widespread use:a. Versatility: These devices can be customized to meet specific requirements, making them suitable for a wide range of applications.b. Precise Control: Rotating potential meters allow for precise adjustments, ensuring accurate measurements and control of electrical signals.c. Durability: With proper maintenance, potentiometers can have a long lifespan, making them reliable components in various systems.d. Cost-Effective: Rotating potential meters are relatively inexpensive compared to other measurement and control devices, making them a cost-effective solution for many applications.Conclusion (100 words) Rotating potential meters are indispensable devices in modern technology, offering a range of features that make them versatile and reliable. From audio equipment to industrial control systems, these devices provide precise measurements and control of electrical signals. Their functionality, types, applications, and advantages make them an essential component in various industries. As technology continues to advance, rotating potential meters will undoubtedly play a crucial role in shaping the future of measurement and control systems.

What market policies does Fine -tuning potential meter have?

Title: Fine-Tuning Potential Meter: Unleashing the Power of Market PoliciesIntroduction (100 words) Market policies play a crucial role in shaping the economic landscape of any country. One such policy that has gained significant attention is the fine-tuning potential meter. This article aims to explore the concept of the fine-tuning potential meter and its implications for market policies. By delving into its definition, benefits, and potential drawbacks, we can gain a comprehensive understanding of how this policy can be utilized to optimize economic growth and stability.Defining the Fine-Tuning Potential Meter (200 words) The fine-tuning potential meter is a market policy that involves adjusting various economic indicators to maintain a stable and sustainable growth rate. It is a proactive approach that allows policymakers to make timely interventions to prevent economic imbalances and crises. The policy relies on monitoring key indicators such as inflation, unemployment, interest rates, and exchange rates to gauge the overall health of the economy.Benefits of the Fine-Tuning Potential Meter (300 words) 1. Economic Stability: By continuously monitoring and adjusting economic indicators, the fine-tuning potential meter helps maintain stability in the economy. It allows policymakers to identify potential risks and take corrective measures before they escalate into major crises.2. Efficient Resource Allocation: The fine-tuning potential meter enables policymakers to allocate resources more efficiently. By closely monitoring economic indicators, they can identify sectors that require support or intervention, ensuring that resources are directed to areas with the highest potential for growth.3. Inflation Control: One of the primary objectives of the fine-tuning potential meter is to control inflation. By adjusting interest rates and other monetary policies, policymakers can curb inflationary pressures and maintain price stability, which is crucial for sustainable economic growth.4. Employment Generation: The fine-tuning potential meter can help policymakers address unemployment issues. By monitoring indicators such as job creation and labor market conditions, they can implement policies that promote job growth and reduce unemployment rates.5. Crisis Prevention: The fine-tuning potential meter acts as an early warning system, allowing policymakers to identify and address potential crises before they spiral out of control. This proactive approach minimizes the impact of economic shocks and reduces the likelihood of severe recessions.Drawbacks and Challenges (300 words) 1. Data Accuracy and Reliability: The effectiveness of the fine-tuning potential meter relies heavily on accurate and reliable data. However, gathering and analyzing real-time data can be challenging, leading to potential inaccuracies that may hinder the policy's effectiveness.2. Policy Lag: Implementing policy changes based on economic indicators takes time. By the time policymakers identify a problem and take action, the situation may have worsened. This lag can limit the effectiveness of the fine-tuning potential meter in addressing rapidly evolving economic conditions.3. Unintended Consequences: Adjusting economic indicators can have unintended consequences. For example, increasing interest rates to control inflation may lead to reduced consumer spending and slower economic growth. Policymakers must carefully consider the potential side effects of their interventions.4. Political Interference: The fine-tuning potential meter can be susceptible to political interference, as policymakers may be tempted to manipulate economic indicators for short-term political gains. This interference can undermine the policy's effectiveness and credibility.Conclusion (100 words) The fine-tuning potential meter is a market policy that holds immense potential for optimizing economic growth and stability. By continuously monitoring and adjusting economic indicators, policymakers can proactively address imbalances, control inflation, and promote employment generation. However, challenges such as data accuracy, policy lag, unintended consequences, and political interference must be carefully managed to ensure the policy's effectiveness. With proper implementation and a commitment to evidence-based decision-making, the fine-tuning potential meter can be a powerful tool in the hands of policymakers, enabling them to steer economies towards sustainable growth and prosperity.

What is the status of the Tape industry?

Title: The Tape Industry: A Resilient Legacy in the Digital AgeIntroduction (100 words) The tape industry, once a dominant force in data storage and entertainment, has witnessed a significant decline in recent years due to the rise of digital technologies. However, despite the challenges posed by the digital revolution, the tape industry has managed to adapt and find new applications, ensuring its continued relevance in various sectors. This article explores the current status of the tape industry, its evolution, and the reasons behind its enduring presence in today's fast-paced world.Historical Overview (200 words) Tape technology has a rich history dating back to the early 20th century when it was primarily used for audio recording. The introduction of magnetic tape revolutionized the music industry, allowing for the mass production of music albums. In subsequent decades, tape technology expanded into other domains, including video recording, data storage, and backup solutions.Decline in the Digital Era (200 words) The advent of digital technologies, such as CDs, DVDs, and later cloud storage, posed a significant challenge to the tape industry. The compactness, ease of use, and higher storage capacities offered by digital media led to a decline in the demand for tapes. Consumers and businesses alike embraced the convenience of digital formats, leaving tape manufacturers struggling to maintain their market share.Adaptation and New Applications (300 words) Despite the decline, the tape industry has managed to adapt and find new applications, ensuring its survival in niche markets. One such area is data storage and backup solutions. Tape technology offers advantages such as high capacity, long-term data retention, and cost-effectiveness, making it an attractive option for organizations dealing with massive amounts of data. Tape libraries and robotic systems have been developed to automate the process, further enhancing its appeal.Moreover, the tape industry has found a new lease on life in the entertainment sector. Audiophiles and music enthusiasts appreciate the warm, analog sound produced by tape recordings, leading to a resurgence in the popularity of cassette tapes and reel-to-reel formats. This niche market has allowed tape manufacturers to cater to a specific audience seeking a unique audio experience.Additionally, the tape industry has found applications in specialized fields such as surveillance systems, where tapes offer reliable and secure storage for video footage. The durability and longevity of tapes make them ideal for long-term archiving, ensuring critical data remains accessible for extended periods.Future Prospects and Innovations (300 words) While the tape industry has faced significant challenges, it continues to evolve and innovate to meet the demands of modern technology. One notable development is the introduction of Linear Tape-Open (LTO) technology, which offers higher storage capacities and faster data transfer rates. LTO tapes have become the preferred choice for many organizations requiring reliable and scalable backup solutions.Furthermore, advancements in tape coating technologies have improved the durability and longevity of tapes, making them more resistant to wear and tear. This ensures that data stored on tapes remains intact and accessible for extended periods, making them an attractive option for long-term archival purposes.Conclusion (100 words) In conclusion, the tape industry has experienced a decline in recent years due to the rise of digital technologies. However, it has managed to adapt and find new applications, ensuring its continued relevance in various sectors. From data storage and backup solutions to niche markets in entertainment and surveillance, tape technology offers unique advantages that cannot be easily replicated by digital media. With ongoing innovations and advancements, the tape industry is poised to maintain its presence and cater to specific needs in today's fast-paced digital age.

Adjustable power resistor Component Class Recommendation

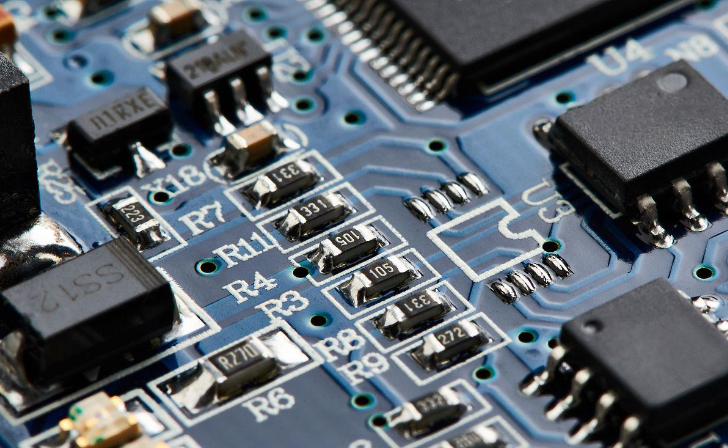

Title: Choosing the Right Adjustable Power Resistor: A Comprehensive Component Class RecommendationIntroduction (100 words) Adjustable power resistors are essential components in various electronic applications, providing precise control over resistance values and power dissipation. However, selecting the right resistor for a specific application can be challenging due to the wide range of options available. This article aims to provide a comprehensive component class recommendation for adjustable power resistors, covering key factors such as power rating, resistance range, temperature coefficient, and package type. By understanding these considerations, engineers and hobbyists can make informed decisions when choosing adjustable power resistors for their projects.1. Power Rating (200 words) The power rating of an adjustable power resistor determines its ability to handle heat dissipation. It is crucial to select a resistor with a power rating that exceeds the maximum power dissipation expected in the application. Failure to do so can result in overheating, leading to performance degradation or even component failure. When choosing a power rating, consider both the continuous power rating and the short-term overload capability. Higher power ratings often come with larger package sizes, so it is essential to balance power requirements with space constraints.2. Resistance Range (200 words) The resistance range of an adjustable power resistor determines its versatility in different applications. It is crucial to select a resistor with a resistance range that covers the desired values for the specific project. Consider the minimum and maximum resistance values required, as well as the desired resolution. Some adjustable power resistors offer a wide resistance range, allowing for fine-tuning of resistance values, while others are more limited in their range. Additionally, consider the tolerance of the resistor, as it affects the accuracy of the resistance value.3. Temperature Coefficient (200 words) The temperature coefficient of an adjustable power resistor indicates how its resistance value changes with temperature variations. It is crucial to select a resistor with a low temperature coefficient to ensure stability and accuracy in different operating conditions. A low temperature coefficient minimizes resistance drift due to temperature changes, which is particularly important in applications where precise resistance values are required. Temperature coefficients are typically expressed in parts per million per degree Celsius (ppm/°C), with lower values indicating better stability.4. Package Type (200 words) The package type of an adjustable power resistor determines its physical dimensions, mounting options, and ease of integration into a circuit. Common package types include through-hole, surface mount, and chassis mount. Through-hole resistors are suitable for prototyping and hand-soldering, while surface mount resistors are smaller and more suitable for automated assembly processes. Chassis mount resistors are designed for high-power applications and often feature additional heat sinks for efficient heat dissipation. Consider the available space on the PCB or in the system enclosure when selecting the package type.Conclusion (100 words) Choosing the right adjustable power resistor is crucial for ensuring optimal performance and reliability in electronic applications. By considering factors such as power rating, resistance range, temperature coefficient, and package type, engineers and hobbyists can make informed decisions when selecting adjustable power resistors for their projects. It is essential to carefully evaluate the specific requirements of the application and choose a resistor that meets those requirements while considering space constraints and cost considerations. With the right adjustable power resistor, electronic systems can achieve precise control over resistance values and power dissipation, leading to improved overall performance.

Numerical display potentiometer Component Class Recommendation

Title: Exploring the Versatility of Numerical Display Potentiometer ComponentsIntroduction: In the world of electronic components, potentiometers play a crucial role in controlling and adjusting electrical signals. These versatile devices are widely used in various applications, ranging from audio equipment to industrial machinery. One specific type of potentiometer that has gained popularity in recent years is the numerical display potentiometer. In this article, we will delve into the features, applications, and benefits of this component class, highlighting its importance in modern electronic systems.1. Understanding Numerical Display Potentiometers: Numerical display potentiometers, also known as digital potentiometers, are electronic components that combine the functionality of a traditional potentiometer with a built-in numerical display. This display allows users to directly visualize and adjust the resistance value, making it easier to fine-tune the desired output. These components are available in various configurations, including single-turn and multi-turn options, each offering unique advantages depending on the application.2. Features and Specifications: Numerical display potentiometers come with a range of features and specifications that make them suitable for diverse applications. Some key features include:a. Resolution: The resolution of a digital potentiometer determines the smallest incremental change in resistance that can be achieved. Higher resolution allows for more precise adjustments.b. Interface Options: These components can be controlled using various interfaces, such as I2C, SPI, or UART, enabling seamless integration into digital systems.c. Memory Storage: Some digital potentiometers offer non-volatile memory storage, allowing them to retain their settings even after power is disconnected.d. Temperature Stability: Temperature variations can affect the accuracy of potentiometers. Numerical display potentiometers often incorporate temperature compensation mechanisms to ensure stable performance across different environments.3. Applications of Numerical Display Potentiometers: The versatility of numerical display potentiometers makes them suitable for a wide range of applications. Here are a few notable examples:a. Audio Equipment: Digital potentiometers find extensive use in audio systems, such as mixers, amplifiers, and equalizers. The ability to precisely adjust resistance values allows for fine-tuning audio signals and achieving optimal sound quality.b. Industrial Control Systems: In industrial settings, numerical display potentiometers are employed in control panels and automation systems. Their digital interface enables remote control and monitoring, simplifying the operation of complex machinery.c. Test and Measurement Instruments: Digital potentiometers are essential components in test and measurement instruments, including oscilloscopes, signal generators, and power supplies. The numerical display facilitates accurate calibration and adjustment of these instruments.d. Consumer Electronics: From household appliances to gaming consoles, digital potentiometers are used in various consumer electronics devices. Their compact size, ease of integration, and precise control make them ideal for volume control, brightness adjustment, and other user interface functions.4. Benefits and Advantages: Numerical display potentiometers offer several advantages over traditional potentiometers:a. Precise Control: The numerical display allows for precise adjustments, eliminating the guesswork associated with analog potentiometers.b. Space Efficiency: Digital potentiometers are often more compact than their analog counterparts, making them suitable for space-constrained applications.c. Remote Control: The digital interface of these components enables remote control and automation, enhancing system flexibility and ease of use.d. Cost-Effectiveness: While numerical display potentiometers may have a higher initial cost, their long-term benefits, such as reduced maintenance and increased accuracy, make them cost-effective solutions.Conclusion: Numerical display potentiometers have revolutionized the way we control and adjust electrical signals in modern electronic systems. Their ability to provide precise resistance adjustments, coupled with the convenience of a built-in numerical display, makes them indispensable components in a wide range of applications. As technology continues to advance, the demand for these versatile components is expected to grow, further solidifying their importance in the world of electronics.