The production process of mainstream PMIC (Power Management Integrated Circuit) voltage regulators, specifically linear regulator controllers, involves several stages and technologies. These components play a crucial role in regulating and stabilizing voltage levels in electronic devices, ensuring their proper functioning. In this article, we will explore the production process of linear regulator controllers, from the initial design phase to the final testing and packaging.

1. Design and Specification: The production process begins with the design and specification phase. Engineers and designers work closely to define the requirements and functionalities of the linear regulator controller. This includes determining the desired output voltage, current capacity, input voltage range, and other specifications. The design team also considers factors like efficiency, thermal management, and protection features during this phase.

2. Integrated Circuit (IC) Fabrication: Once the design is finalized, the fabrication of the IC begins. This involves using semiconductor manufacturing techniques to create the various layers and components of the linear regulator controller. The fabrication process typically includes steps like wafer preparation, photolithography, etching, deposition, and doping. These steps are performed in a cleanroom environment to ensure the purity and quality of the IC.

3. Testing and Quality Control: After the IC fabrication, the next step is testing and quality control. This involves conducting various tests to ensure that the fabricated IC meets the design specifications and functions correctly. Different types of tests are performed, including electrical tests, functional tests, and reliability tests. Electrical tests check parameters like voltage regulation, load regulation, and line regulation. Functional tests verify the performance of protection features, such as overvoltage and overcurrent protection. Reliability tests assess the IC's performance under different operating conditions, including temperature and humidity variations.

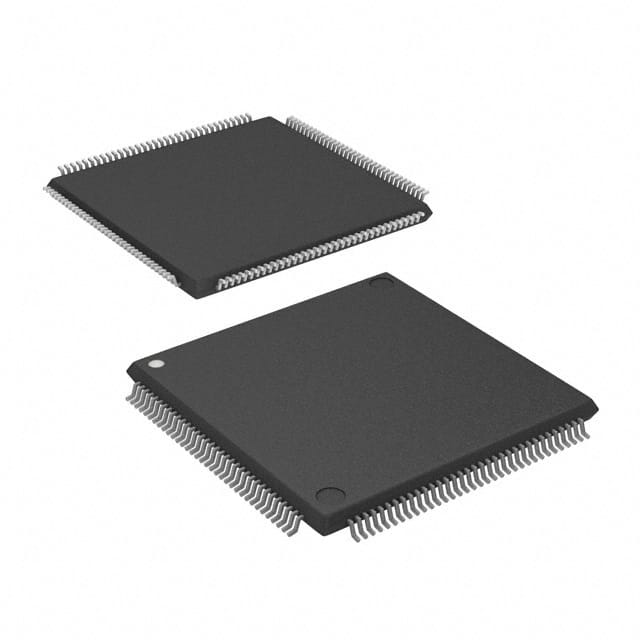

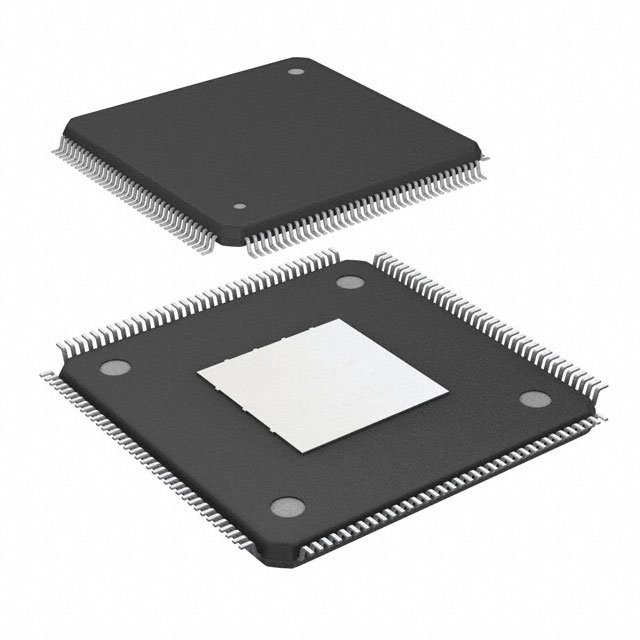

4. Packaging and Assembly: Once the IC passes the testing phase, it is ready for packaging and assembly. Packaging involves encapsulating the IC in a protective casing, which provides mechanical support, electrical connections, and thermal dissipation. There are various packaging options available, such as through-hole packages, surface-mount packages, and ball grid array (BGA) packages. The choice of packaging depends on factors like size, power dissipation, and application requirements.

5. Final Testing and Characterization: After packaging, the linear regulator controllers undergo final testing and characterization. This involves subjecting the packaged ICs to a series of tests to ensure their functionality and performance. The tests include temperature cycling, burn-in tests, and electrical characterization. Temperature cycling tests simulate the IC's behavior under different temperature conditions to assess its reliability. Burn-in tests involve stressing the ICs under accelerated conditions to identify any potential failures. Electrical characterization tests measure parameters like output voltage accuracy, load regulation, and transient response.

6. Quality Assurance and Compliance: Throughout the production process, quality assurance and compliance play a vital role. Manufacturers follow strict quality control procedures to ensure that the linear regulator controllers meet industry standards and customer requirements. Compliance with regulatory standards, such as ISO 9001, ISO 14001, and RoHS (Restriction of Hazardous Substances), is also essential. Manufacturers implement quality management systems and conduct regular audits to maintain consistent quality and compliance.

7. Packaging and Distribution: Once the linear regulator controllers pass all the tests and quality checks, they are packaged and prepared for distribution. The packaged ICs are labeled, barcoded, and stored in appropriate packaging materials to protect them during transportation. Manufacturers ensure proper documentation, including datasheets, application notes, and compliance certificates, is provided with the packaged ICs. The components are then distributed to customers, including original equipment manufacturers (OEMs), electronics distributors, and contract manufacturers.

In conclusion, the production process of mainstream PMIC voltage regulators, specifically linear regulator controllers, involves several stages, including design and specification, IC fabrication, testing and quality control, packaging and assembly, final testing and characterization, quality assurance and compliance, and packaging and distribution. Each stage is crucial in ensuring the functionality, reliability, and quality of these components. By following these processes, manufacturers can produce high-quality linear regulator controllers that meet the demands of various electronic devices.